随着行业逐步迈进自动化应用的时代,节约人力成本必然成为一种趋势。

我公司推出新型循环式储坯机,正是这样一款由储坯笼和升降输送辊台组成的适用于窑炉烧成前 / 后砖坯缓存的新型储坯设备。

As the industry gradually moves into the era of automation applications, saving labor costs will inevitably become a trend.

Our company introduced a new type of cycling compensator, which is a new type of stocking equipment consisting of a stock cage and an

elevating conveyor roller table suitable for caulking the front and rear bricks in the kiln.

产品优势

Product Advantage

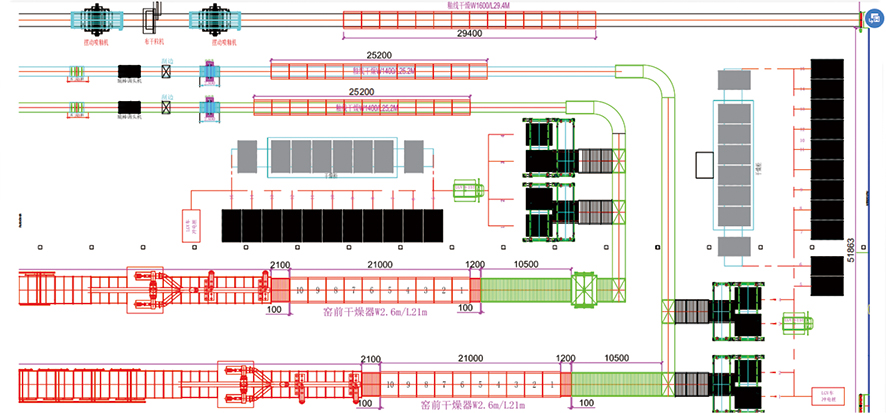

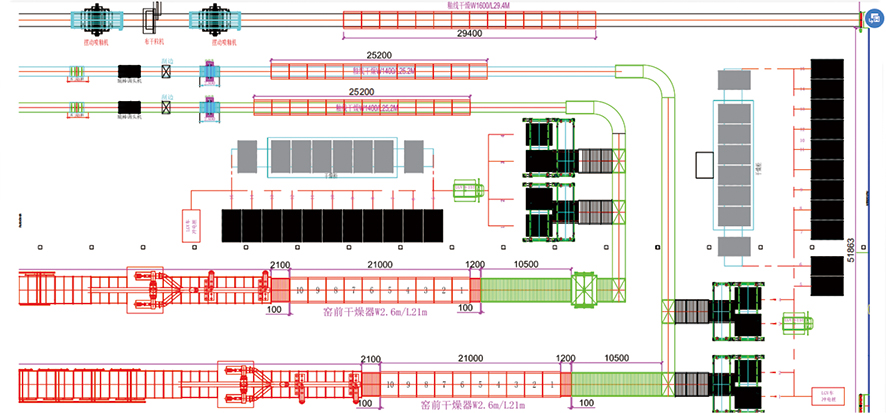

生产线进窑前所有工段,包括送料车间、压机车间、釉线车间工作人员只需要工作 12 小时,即可满足窑炉日产量 14000 平方米。大大节约了人力以及电能。

All the production sections before kiln, including the feed section, press section, glaze line section' s staff only need to work 12 hours, to meet the

daily output of 14,000 square meters furnace. Great savings in manpower and electricity

循环式储坯机配置大容量的缓存储坯笼,以 800 x 800 ( mm ) 的砖坯为例,设置 30 个储坯笼。每个储坯笼最大可达到 259.2m² 的缓存量,并实现智能控制。

在正常 12 小时工作时间内,由釉线输送过来的砖坯,分成两部分控制 : - 部分正常进窑烧成,多出部分由循环式储坯机智能送进缓存储坯笼内,储满后

使用 AGV 无人搬运车自动运送到储坯笼停放区存放。当整条生产线正式储坯机智能送进缓存储坯笼内,储满后使用 LGV 无人搬运车自动运送到储坯笼

停放区存放。当整条生产线正常工作 12 小时,窑前所有工段停止工作,循环式储坯机自动使用 LGV 无人搬运车把储坯笼停放区内的储坯笼按照先后顺

序运送到升降输送辊台处,把储存的砖坯按先进先出原则把砖坯输送进窑炉。

The cycling compensator is equipped with a large- -capacity, buffer- storage blank cage. For example, an 800 x 800 (mm) green tile is used to set

30 stock cages. Each storage cage can achieve a maximum buffer of 259.2m2 and achieve intelligent control.

In the normal 12- -hour working time, the tiles conveyer by the glaze line are divided into two parts: a part of the normal incoming kiln is burned,

and the excess part is intelligently fed into the buffer storage cage by the circulating stocker and used after being full. AGV unmanned vans are

automatically transported to the storage area for storage of cages. When the entire production line works normally for 12 hours, all sections in the

kiln stop working, and the circulating stocker automatically uses the LGV unmanned van to transport the storage cages in the storage area of the

cage to the elevating conveyor roller table in the sequence. The stored bricks are conveyed into the furnace on a first- in-first- -out basis.

产品亮点

Product highlights

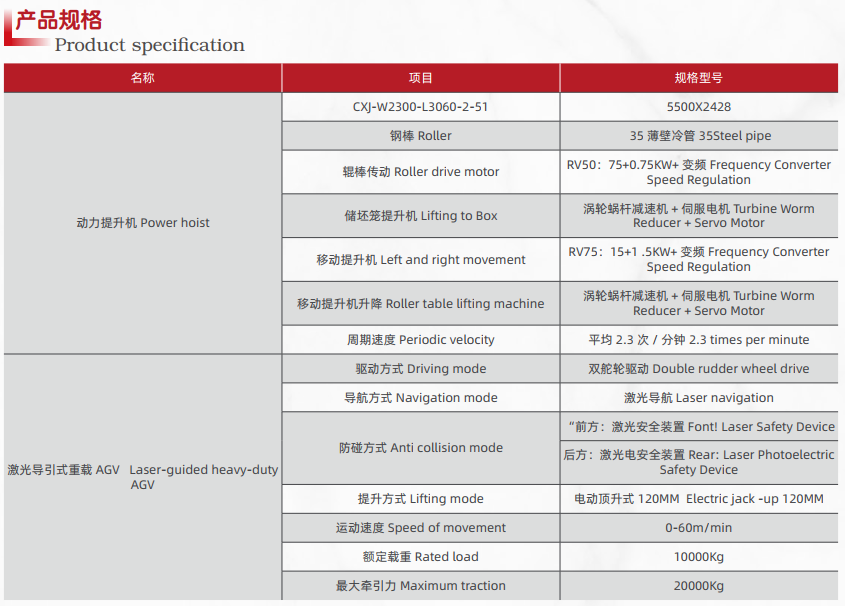

智能循环储坯系统使用的 LGV 无人搬运车,在完全不需要人的前提下,能够沿设定的激光导航引路行驶,具有安全保护以及各种移载功能,透过电脑指

令控制源源不断地补充储坯笼容量,满足生产需求。使用激光导航系统,使运行路线灵活多变 , 随意设定更改线路,特别是转产品时特别方便实用。

The LGV unmanned van used in the intelligent circular billet storage system can travel along the set laser The LGV unmanned van used in the

intelligent circular billet storage system can travel along the set laser the computer. The order control source continuously supplements the capacity

of the bank cage to meet production requirements.' The use of a laser navigation system makes the running route flexible and allows you to change

the route at your disposal. This is especially convenient and practical when you switch products.

AGV 无人搬运车能够人工固定在某个地点充电,也可以在不工作的情况下自动去到某充电站自行充电。电量自动检测,当检

测到电量低于设定值,AGV 无人搬运车会自行给电池充电,无需要操作人员介入。电池可多次重复充电。

产品升级

Product Advantage

可配置“互联网 +”技术 : 通过 Ethernet\wifi\3G\4G 网络, 嵌入云端技术, 实现数据采集和分析处理,全方位实时监控生产。

The AGV unmanned truck can be manually fixed at a certain place to charge, or it can automatically go to a charging station to charge itself when it is not working. Automatic detection of electricity, when the detected power is lower than the set value, AGV unmanned van will charge the battery by itself, no need for operator intervention. The battery can be repeatedly charged. [product upgrade]: Configurable "Internet +" technology: Through the Ethernet \ wifi \ 3G \ 4G network,embedded cloud technology, data acquisition and analysis and processing, all-round real-time monitoring of production.